Earlier this year I had the opportunity to visit the Cambo HQ and Factory in The Netherlands to take a look at how the Cambo products we all know and love are designed, machined, and hand assembled to perfection.

Cambo started producing cameras in 1947 and has the distinction of being the first company to produce an all metal medium format camera. Since then they have always built a reputation for high quality, precision engineered cameras, stands and other studio equipment (and accessories too!).

In 1965 the factory was re-located to its current location in Kampen, where it remains to this day.

The Cambo machine shop now contains five computer powered machine tools capable of producing individual parts out of solid aluminum at a steady and fast pace. As well as many other tools from de-burring tanks and even a tool for making their own ground glass inserts.

This portion of the process is all computer controlled. Aluminum blanks are loaded into cradles, which are then bulk loaded into the CNC machines.

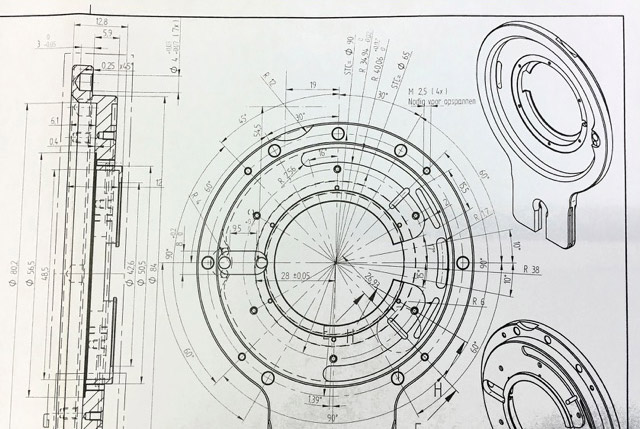

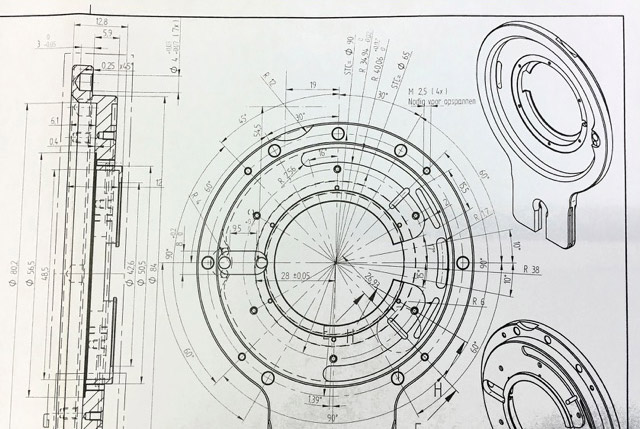

Every product is designed with the aid of a computer to very precise tolerances, some even down to the one hundredth of a millimeter range. These designs are translated and loaded into the CNC mills alongside the blanks.

The CNC machines are designed to run with or without human interaction, allowing work to be completed around the clock. Depending on the component, each individual part can go from raw blank to machined part in as little as 30 seconds, to around 30 minutes for larger parts.

Because all of this work is done in house, products can be revised and updated features can be added if needed. This also means that prototype parts can be machined and tested very quickly, making the final product ready for market much faster.

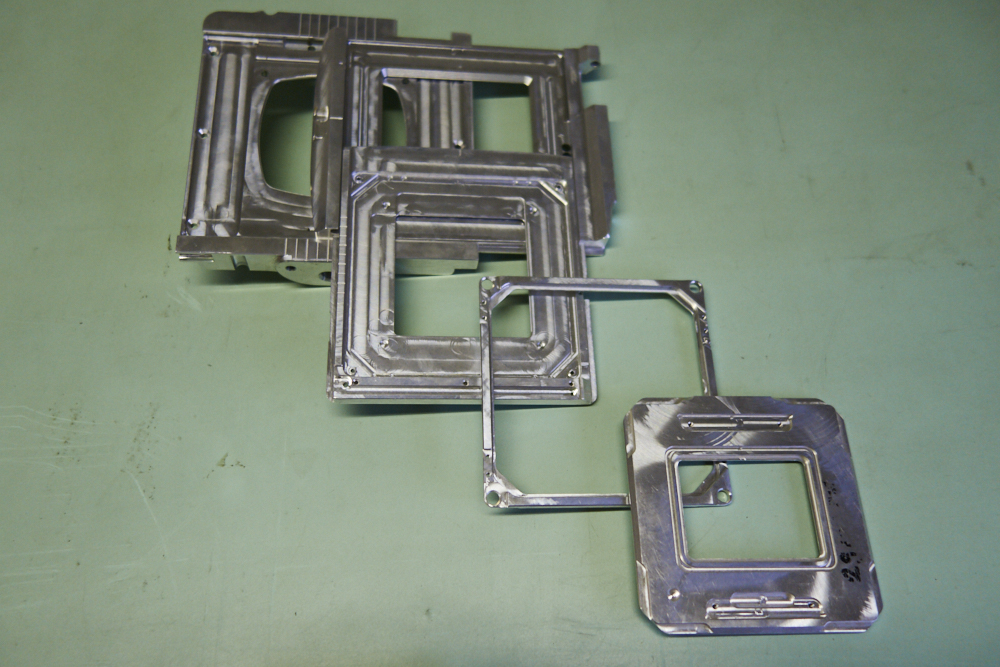

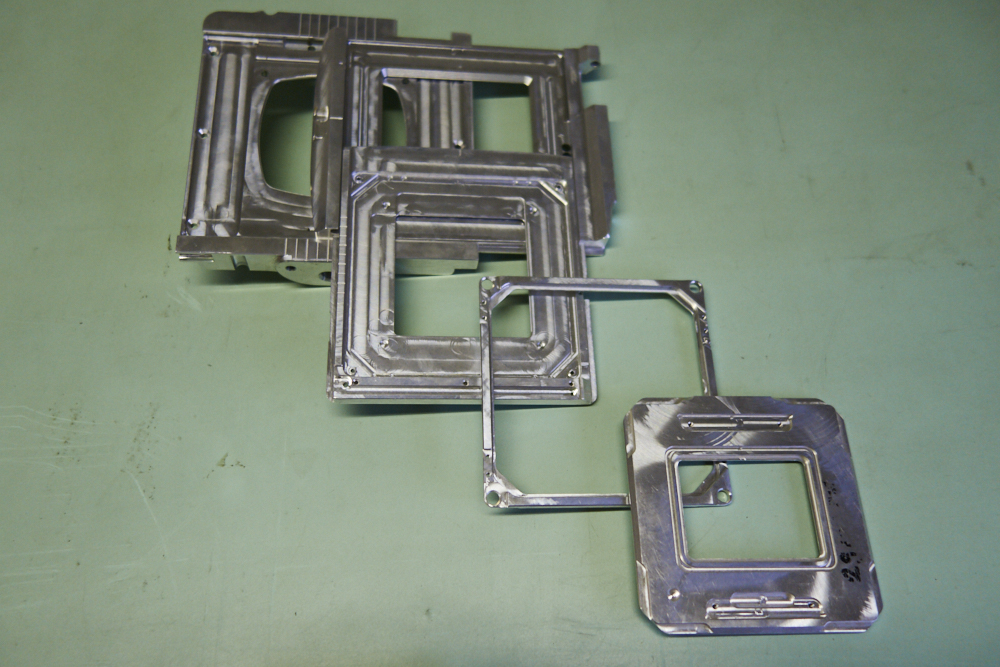

Each of these individual components were once solid aluminum, and now are archived as masters for test fitting and to compare each batch of products that come off the production line.

This shows the complexity and tight tolerances of each Cambo product. For example the WRS-1200 shift mechanism is made up of 5 different parts, each one having to fit perfectly within it’s mate. If even one piece is out of spec, the entire camera cannot be used properly.

After machining and powder coating, the parts are moved into the assembly shop.

This organized chaos is where a team of trained professionals assemble each Cambo product by hand, pulling parts as needed to complete batches of items.

Each assembly technician is an expert in specific product lines, and performs both assembly and repair for products as needed. This allows for multiple products to be assembled simultaneously, and keep production wait times as low as possible.

During and after assembly each product is also checked to verify that each of the careful tolerances are within range.

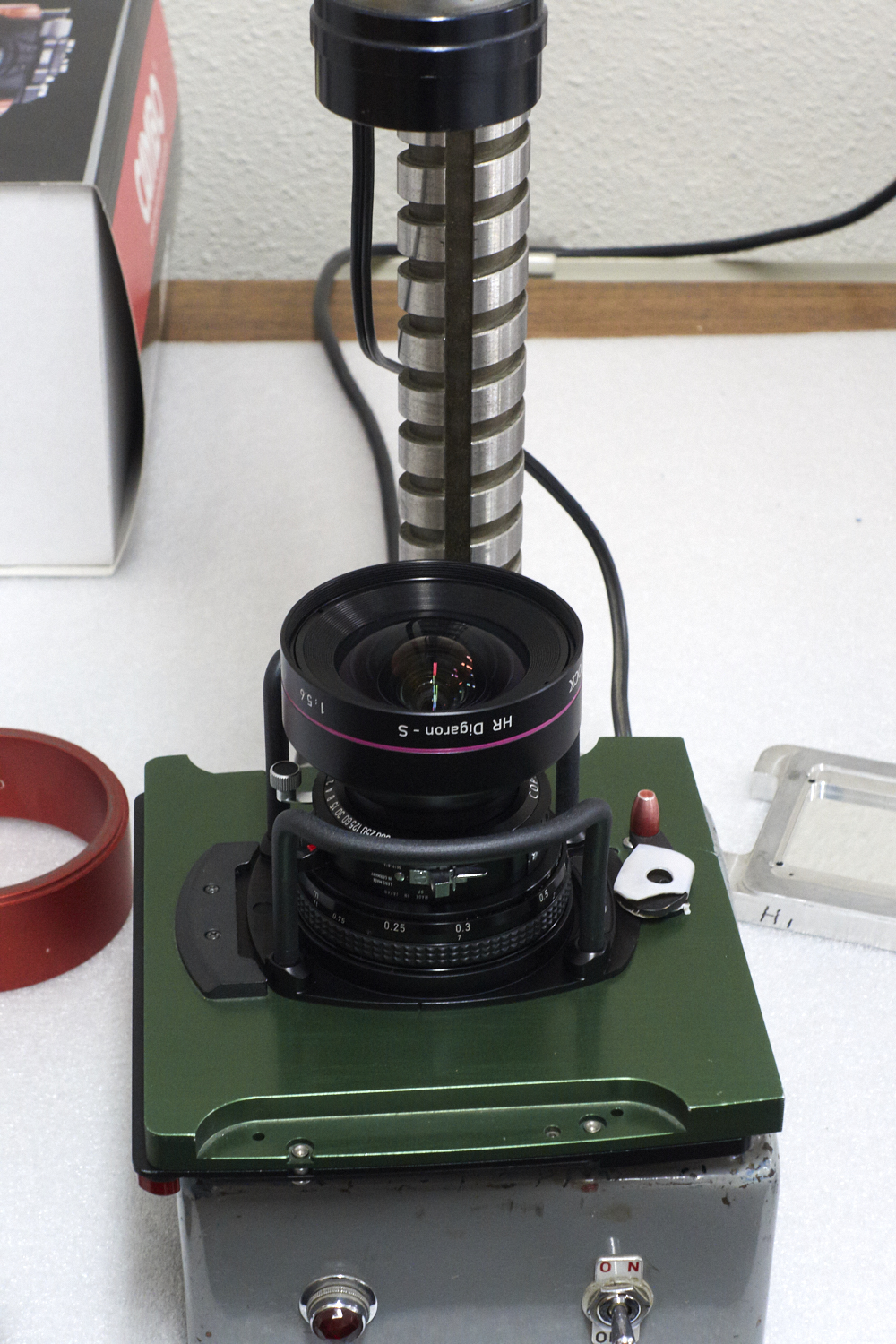

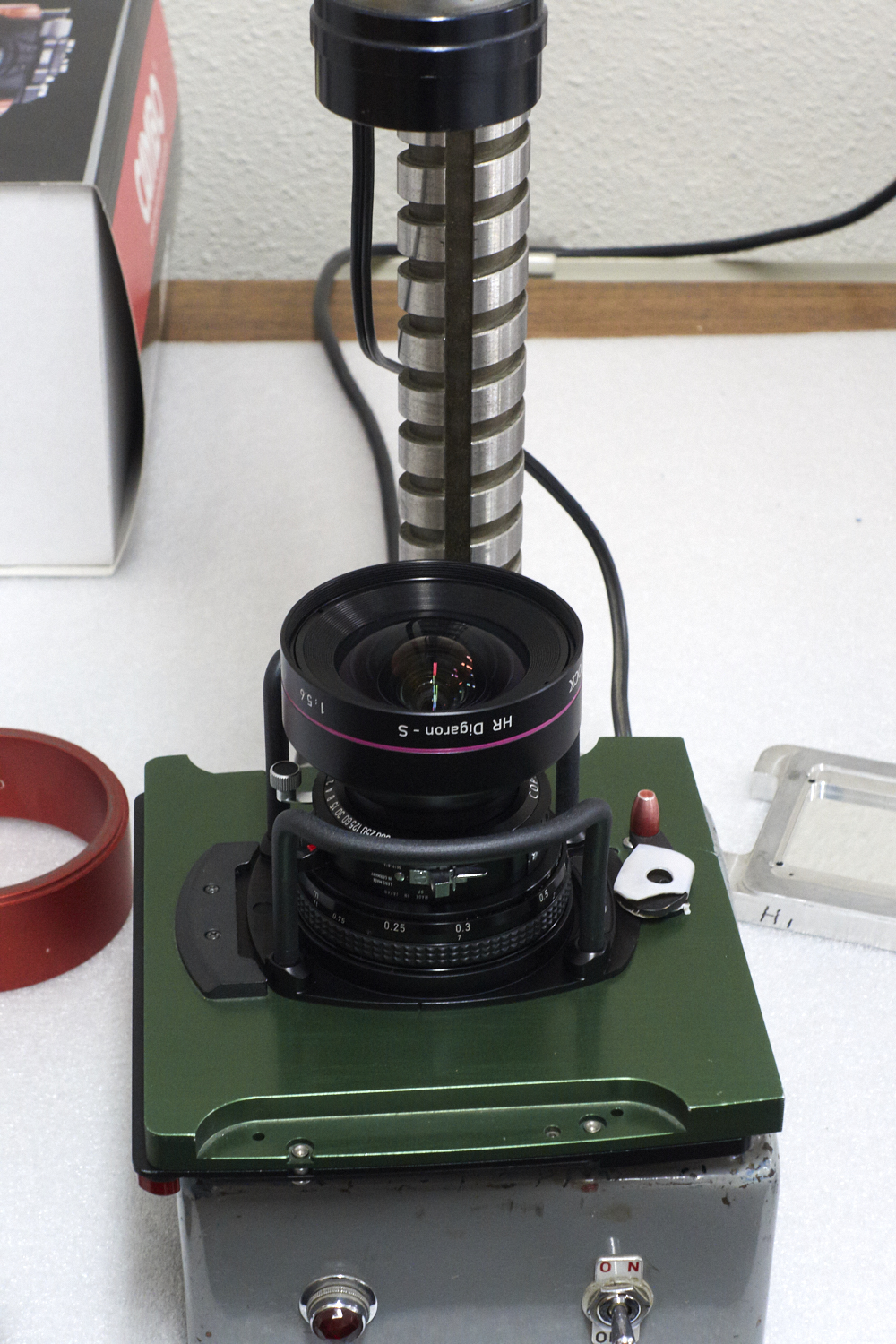

Special die cut blocks are used to emulate the location of the film plane or digital back to ensure correct measurements are maintained.

WRS Lens Panels too are tested and calibrated to fine tune each individual lens to its machined home.

Once each part has been carefully assembled it is packaged and placed into storage, where it waits for an order to be placed.

Not only does Cambo keep well in stock of new products, but spare parts from products past are also stored within the assembly facility. Each part being carefully cataloged so that individual pieces can be grabbed in the event of a repair or replacement.

During my visit, a long time customer brought in an older model studio stand that aside from needing a new set of brake pads installed in its central column, looked and functioned fantastically. Even more impressive is that this stand was over 30 years old, and after a little refreshing still worked as well as the day it was purchased.

It’s easy to see that the upmost care is given to every part of the design, machining, assembly, and longevity of each Cambo product. So when you purchase Cambo equipment, you aren’t just buying into a brand. You truly are investing in a system that was built with you in mind.